Swimwear manufacturing is the crucial process that links design concepts with functional, wearable garments. It transforms the designer’s vision into tangible products ready for the consumer. Furthermore, the quality of construction directly impacts the consumer’s wearing experience, comfort, fit, and overall perception of the garment’s design and value. At its core, swimwear manufacturing involves the precise cutting and assembly of fabric panels according to specific patterns and technical specifications (tech packs). While seemingly straightforward, this process demands significant technical expertise and specialized knowledge, particularly given the unique properties and handling requirements of stretch fabrics inherent to swimwear.

This article focuses on a cornerstone of garment production: the sewing machine. Its history dates back to late 18th-century England, with Thomas Saint’s 1790 invention, initially designed for stitching leather and canvas. Since then, technological advancements have yielded a vast range of sewing machines with increasingly specialized functions and refined capabilities, essential for modern apparel manufacturing. This includes swimwear production, which often relies on a specific range of sewing machines adapted for swimwear fabrics and construction techniques due to the common use of high-stretch materials.

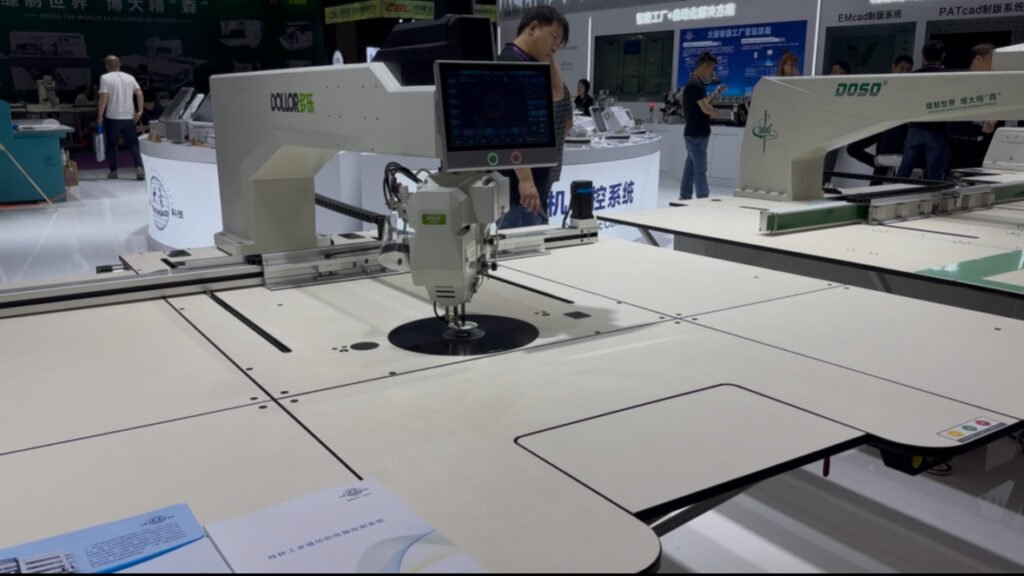

Let’s examine the industrial lockstitch machine. As a fundamental piece of industrial sewing equipment, it’s a common sight in apparel factories, including those specializing in swimwear. It often forms part of the essential lineup of sewing machines for swimwear production, typically used alongside more specialized stretch-stitch machines (like overlockers and coverstitch machines, which handle elastic seams more effectively). While models from different manufacturers may feature minor variations, their core components and principles of operation are largely universal. The lockstitch machine is valued for its robustness, reliability, and relative ease of operation for specific tasks. Speed is typically controlled via a foot pedal (treadle), while stitch length is adjusted using a dedicated dial or regulator.

The lockstitch machine creates a straight stitch (Stitch Type 301) known for its neat, consistent appearance. A defining characteristic is that the stitch formation looks virtually identical on both the top (needle side) and underside (bobbin side) of the fabric. This structure results in a strong, durable seam with good tensile strength. However, it’s crucial to note that this stitch offers limited stretch. This characteristic makes the lockstitch suitable for specific operations in swimwear construction (like attaching labels, creating non-stretch reinforced areas, or certain finishing steps) rather than primary seams requiring high elasticity. Therefore, considering it the sole “swimwear sewing machine” would be inaccurate; it’s one important type among others.

As a foundational piece of equipment, the cost of an industrial lockstitch machine can vary significantly based on brand, features, and motor type, often starting upwards of 700 USD for reliable models. At YISWIM, we operate a fleet of nearly 100 such machines. It is the coordinated work of these machines – part of our broader swimwear sewing machine inventory – applying thread to fabric stitch by stitch, that translates detailed designs from technical packages and patterns into the high-quality swimwear our customers expect. This highlights the essential role of reliable machinery, including the versatile lockstitch, and skilled operators in large-scale apparel production.